Pureté - Pure taste, pure creativity

The sensorial richness of cocoa

Fermentation is an essential first step in the development of flavors in chocolate. The Q-Fermentation™ technique enables the farmers to create homogeneous and exceptional fermentations, leading to beans of exceptional quality with intense pure cocoa taste.

Cocoa Horizons

Cacao Barry® is proud to support the Cocoa Horizons Foundation in its mission to improve the living conditions of cocoa producers and their communities. This is achieved through the promotion of sustainable, entrepreneurial, and optimized farming.

A unique farmer-to-chef process

A unique farmer-to-chef process to offer you the best of nature while encouraging longevity of farmers' engagement

- Optimized fermentation for pure flavours

- Cocoa farmers trained in good agricultural practices in order to protect plantations, maximize yields and sustainably increase their incomes.

- Cocoa beans 100% traceable

- Quality checks from cocoa beans to chocolate

- Customized chocolate processing to protect the natural flavours of cocoa

Pureté

From plantation to cocoa beans

1) Cocoa Farmers

Cacao Barry® has embarked on an innovative collaboration with 5000 farmers & 16 cooperatives in the Ivory Coast with the aim to improve the supply of quality cocoa within our Pureté range.

- 93% of cocoa farmers own their plantation

- Average farm size: 3,6 ha

- Average total cocoa produced per farmer: 1,5 mT

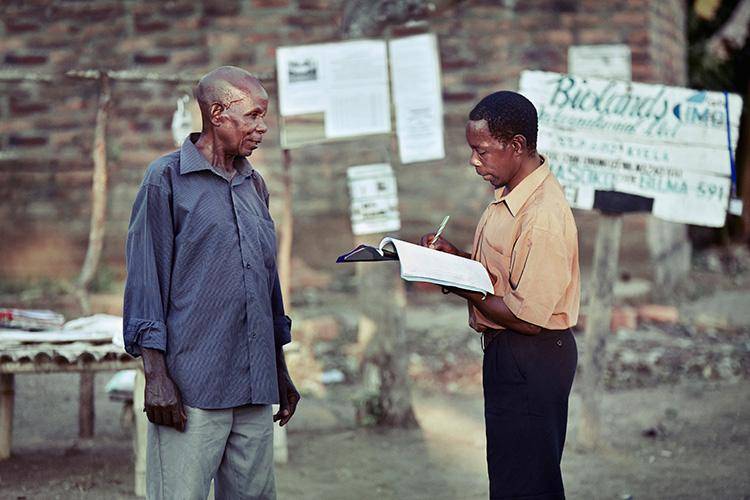

2) Cocoa farmers training & team on site

Cocoa farmers are trained on Good Agricultural Practices and Processes in all steps of the harvest in order to ensure sustainable cocoa.

To assure the conditions are respected, there are the following personnel in place:

- 4 sourcing agents

- 4 sustainability regional managers

- 6 Q-fermentation™ agents

3) The harvest

Cocoa farmers know when the cocoa pods can be harvested by their colour and have the skills to select healthy mature cocoa pods with a wooden stick. Closed cocoa pods can be stored for three days maximum after harvest. Once the Cocoa pods are opened the cocoa farmers pick the fruits by hand and then start the fermentation process.

4) Fermentation

The fermentation science is key as it brings to life the energy of the terroir. Cocoa farmers are trained in Q-Fermentation™ technique that enables them to create homogeneous and exceptional fermentation, yielding beans of exceptional quality close to zero-impurities or off-flavours and with an intense pure natural cocoa taste. To start the fermentation, a side with shade is selected by the cocoa farmers. They create a pile with 50 kilos of beans by hand and naturally optimize the fermentation process. Farmers cover the pile with banana leaves for 2 days. After 2 days, the cocoa farmers mix the pile by hand once again. After a total of 4 days, the fermentation process is finalized.

5/ Sun drying

Natural sun-drying further enhances the fl avour development. Drying is essential for stopping the fermentation process and for storage. Optimal drying ensures that the fl avour precursors all remains inside the beans. The drying method used is to spread out the beans on bamboo mat and let them dry in the sun’s warming rays. The beans are turned regularly so that they dry evenly and retain just a fraction of their moisture content: 6 to 8% is ideal. Beans are dried for a good 5 days.

6/ Quality check

Our 4 trained quality centers in Ivory Coast perform sensory checks to ensure Q-fermentation™ has been applied.

7/ Cocoa farmers rewarded

To reward cocoa farmers engagement in supplying the the purest fl avours of Q-fermented beans sustainably, they are paid a premium (30 FCFA / kg).

8/ Traceability

The farmers and their crops are registered to ensure 100% traceability of the Q-fermented beans. A sourcing contract is set up between our buying site in Ivory Coast and cooperative for a certain volume and for a certain crop per year. Segregated collection of cocoa:

- Separate storage of cocoa at cooperative level

- Separate transportation

- Separate documentation

- List of registered farmers

- Separate storage of cocoa

- Separate shipment to Europe

9/ Transport

Once approved and registered, the Q-fermented beans are transported to Europe.

From cocoa beans to cocoa mass

10/ Labelling check

Once arrived in our cocoa factory, labelling is rechecked to ensure the bags meet our 100% traceability assurance.

11/ Shelling

Separating the shell from the beans to obtain cocoa nibs.

12/ Roasting

Q-fermented beans have lowest possible temperature and duration for roasting to protect the cacao flavor and avoid off tastes.

13/ Grinding the cocoa nibs

he nibs are refined to obtain a very fine 25 micron cocoa liquor that results in a flavour rich mouthfeel. Grinding is done in three steps to obtain a very fine paste: the cocoa liquor.

From cocoa mass to chocolate

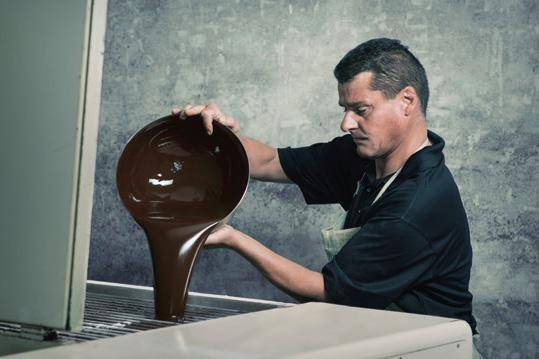

14/ Mixing

In the mixer, our quality approved ingredients are constantly mixed to get the right texture, enabling a correct refi ning.

15/ Grinding the chocolate

The paste is refined through five rolls for the finest particle size that brings long lasting taste and smooth melting.

16/ Conching

Careful conching of the chocolate refi nes the taste to enhance pure cocoa flavour and lower humidity and acidity. The signifi cant friction blunts particles for perfect fineness. For our Pureté range, we adjust our conching criteria to enhance the purest cocoa flavors.

17/ Quality checks

During all processes quality checks on fat content, viscosity, particle size and fluidity are checked to ensure the fibest end result.

From chocolate to chefs

18/ Moulding

After tempering, the chocolate is moulded into blocs or Pistoles™.

19/ Packing

Ocoa™, Inaya™, Excellence, Alunga™ & Lactée Supérieure pistoles™ are packed into best quality bags to ensure flavor protection. The end result is a chocolate with a pure cacao fl avour that is 100% traceable back to farmers.

20/ Workability & pairing

The Pureté range are chocolates that have great workability and a freedom in flavour pairing.

21/ Chefs' creations

A unique farmer-to-chef process offers you the best of nature by encouraging the farmers’ engagement. During all processes, the purest cocoa flavours are protected giving chefs unique chocolates to create with.